Composition of High-Speed Door Frame Structure: A Comprehensive Analysis and Application Guide

1. Main Frame Structure of High-Speed Doors

The frame structure of a high-speed door typically consists of the following core components:

(1) Door Curtain System

The door curtain is the core component, directly affecting durability and sealing. Common materials include:

PVC High-Strength Fabric: Tear-resistant and wear-resistant, suitable for general industrial environments.

Polyester-Coated Fabric: Dustproof and anti-static, ideal for cleanrooms (e.g., food and pharmaceutical industries).

Transparent Window Design: Allows visibility for improved safety.

Key Parameters:

Thickness: 0.8mm–1.2mm

Wind Resistance: Up to Level 12 (approx. 32.7 m/s)

Lifespan: ≥500,000 open/close cycles

(2) Drive System

The drive system determines opening/closing speed and typically uses:

Servo Motor: High-precision control, speeds up to 1.5–2.5 m/s.

Frequency Inverter Control: Ensures smooth acceleration/deceleration, reducing mechanical stress.

Benefits:

Improved Logistics Efficiency: In warehouses, high-speed doors reduce vehicle wait times, increasing throughput by over 30%.

Energy Savings: Rapid closing minimizes air exchange, cutting HVAC energy consumption by ~20%.

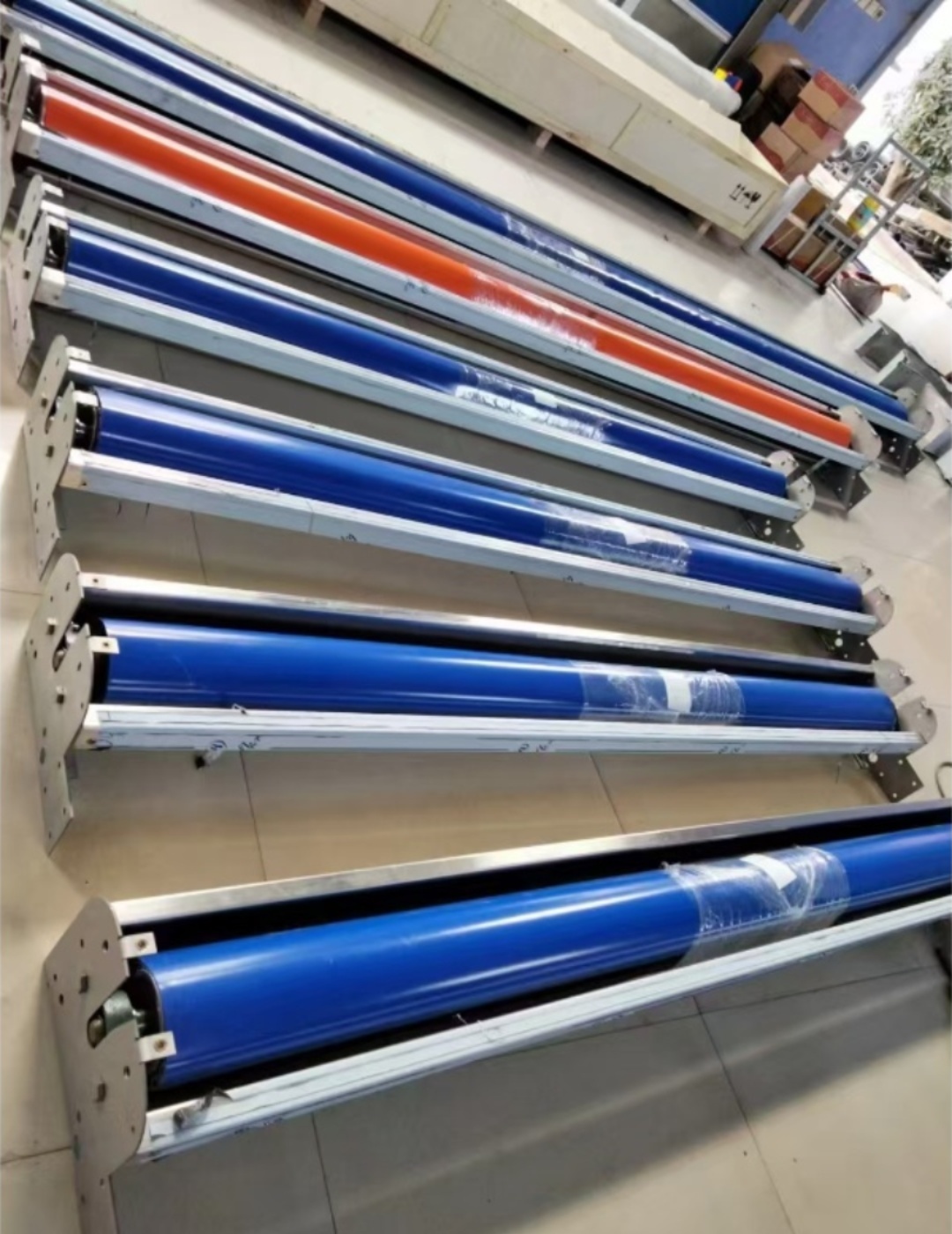

(3) Track and Guide System

The track ensures smooth door movement. Common types include:

Aluminum Alloy Track: Lightweight and corrosion-resistant, ideal for indoor use.

Stainless Steel Track: Highly rust-resistant, suitable for humid or corrosive environments (e.g., cold storage, chemical plants).

Critical Parameters:

Track Width: Typically 100–150mm

Guide Rail Precision: ≤1mm deviation to prevent jamming

(4) Safety Protection System

Safety is critical for high-speed doors, with features such as:

Infrared Photoelectric Sensors: Detect obstacles and trigger automatic reversal to prevent injuries.

Bottom Safety Edge: Stops and reverses upon contact with obstructions.

Emergency Stop Button: Manual override for sudden hazards.

Applications:

Automotive Manufacturing: Prevents collisions with robotic arms.

Food Processing Plants: Blocks unauthorized access to hazardous zones.

(5) Control System

Modern high-speed doors often feature smart control systems:

PLC (Programmable Logic Controller): Supports multiple modes (manual, automatic, remote).

Network Connectivity: Integrates with factory MES for intelligent management.

2. Typical Applications of High-Speed Doors

| Industry | Recommended Door Type | Key Requirements | Benefits |

|---|---|---|---|

| Logistics & Warehousing | High-Speed PVC Door | Frequent cycling, wind resistance | Faster loading/unloading, lower energy loss |

| Pharmaceutical Cleanrooms | Anti-Static Door | Sealed, easy to clean | Complies with GMP, reduces contamination risk |

| Food Processing | Stainless Steel Track Door | Corrosion/mold resistance | Longer lifespan, ensures hygiene |

| Parking Garages | Transparent Window Door | High visibility, impact resistance | Enhances safety, reduces accidents |

3. Why Optimize High-Speed Door Frame Structure?

Lower Maintenance Costs: High-quality tracks and drives reduce failure rates, cutting annual maintenance costs by 40%.

Higher Productivity: 1.5 m/s operation is 3x faster than traditional doors, minimizing logistics delays.

Enhanced Safety: Dual protection (sensors + safety edge) reduces workplace accidents by 90%.

Frequently Asked Questions (FAQ)

Q1: How long do high-speed doors typically last?

A: Under normal conditions, a high-quality high-speed door lasts over 500,000 cycles. At 500 cycles/day, this equals ~3–5 years.

Q2: Can high-speed doors operate in freezing temperatures?

A: Yes, but they require cold-resistant curtains (rated for -30°C) and frost-proof motors, such as those used in cold storage.

Q3: How do high-speed doors withstand strong winds?

A: Choose windproof designs (e.g., reinforced aluminum tracks + multi-point anchoring) with a wind resistance rating up to Level 12.

Q4: Are high-speed doors suitable for outdoor installation?

A: Yes, but they need waterproof motors, rust-proof tracks, and rain covers.

Q5: Are high-speed doors noisy?

A: Premium servo motors and inverter controls keep noise ≤65 dB (similar to normal conversation), ensuring minimal workplace disruption.

By analyzing these factors, we see that the frame structure of high-speed doors directly impacts their performance and lifespan. Selecting the right materials and configurations significantly enhances efficiency, safety, and cost-effectiveness.

Recommended Products

up to date Automatic Door Accessories

- Precision High-Speed Door Drive Motor – Synchronous Servo with Worm Gear Reduction

- High Speed Door Fast Door Servo Motor Permanent Magnet AC-Synchronous Servo Motor with Worm Reductio

- High Speed Door Zippers Industrial Door Zippers

- High Speed Door Zippers Industrial Door Zippers

- 1.5KW Servo Motor & Control Box Set - High-Performance Drive System for Industrial Doors

- 0.75KW Servo Drive System for High-Speed Doors - Reliable & Energy-Efficient Solution

- 0.75KW Servo Motor Control Box Set – Efficient and Stable High-Speed Door Drive Solution

- AOK-AC123 Electric Curtain Wireless Remote / Wear-Resistant Acrylic Crystal Panel Remote

- Manufacturers Foot Pedal Activator Safety Beam Photocell Barrier Sensor For Medical Sliding Doors

- Safety photoelectric switch for high-speed door sensors

- Durable PVC Fast Rolling Door Fittings for Enhanced Security

- Automatic Repair of Zipper Door Plastic/Polymer Rails

- Smart Automatic Door Sensor for Fast Rolling Access Control

- Soft Fast Gate Control System 1.5kw Servo Motor and Control Box

- Automatic Access Control Square Surface Mount Infrared Non-Contact Switch

- Explosion-Proof Reinforced Self-Limiting Electric Heating Belt

- Explosion-Proof Shielded Self-Controlling Temperature Electric Heating Belt

- Heating Belt for Anti-Freezing, Heating and Heat Preservation of Cold Storage Doors

- 40W flame retardant explosion-proof self-limiting electric heating belt

- Safety Beam Sensor Use for Automatic Door