Selection Guide for High-Speed Doors in Food Processing Industry

I. Special Requirements for High-Speed Doors in Food Processing

Food processing environments impose more stringent requirements on high-speed doors than other industries, mainly in the following aspects:

High Hygiene Standards

Door surfaces must be smooth and seamless to prevent bacterial growth

Materials must be corrosion-resistant and withstand daily cleaning/disinfection

Structural design should prevent dust and water accumulation

Strict Environmental Control Needs

Effective isolation between areas with different temperature/humidity

Prevention of cross-contamination and foreign matter entry

Good sealing performance in low-temperature areas

High Operational Efficiency Requirements

Fast opening/closing speed to maintain production rhythm

Strong durability to withstand high-frequency use

High automation to reduce human intervention

II. Suitable High-Speed Door Types for Food Processing

1. Stainless Steel High-Speed Doors

Features:

Made of 304 food-grade stainless steel

Specially treated smooth surface for easy cleaning

Full sealing design to effectively prevent contaminant entry

Optional antibacterial coating available

Applicable Areas:Meat processing workshops, dairy production areas, central kitchens and other places with extremely high hygiene requirements

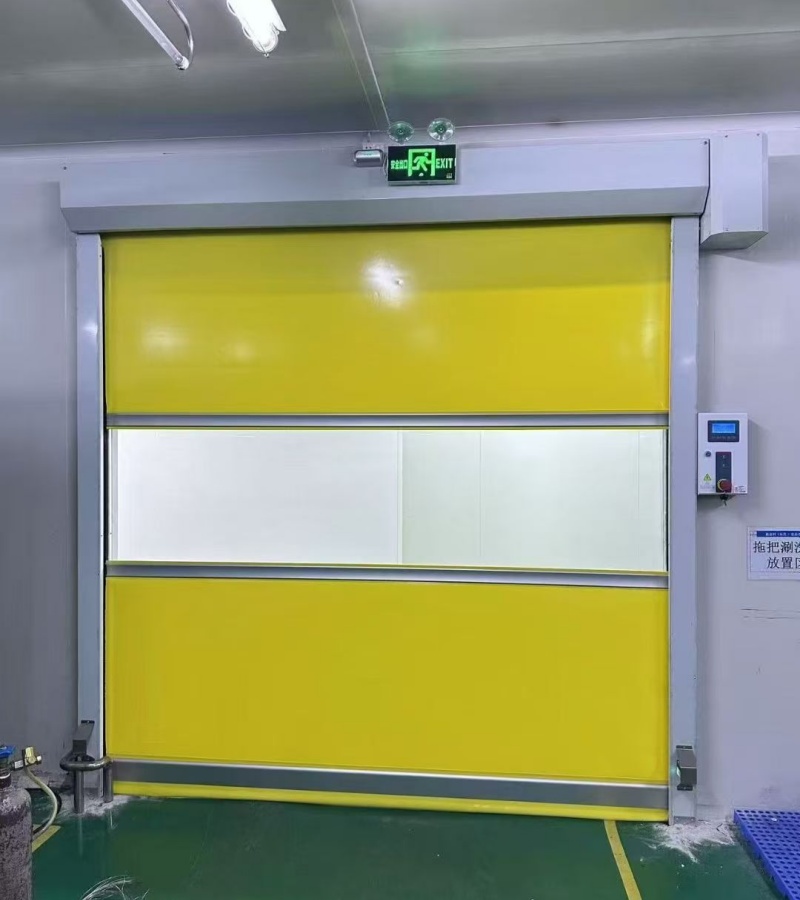

2. PVC Strip High-Speed Doors

Features:

Food-grade PVC material meeting hygiene standards

Transparent window design for interior visibility

Excellent low-temperature resistance, suitable for cold storage

Bottom sealing strip ensures tightness

Applicable Areas:Packaging areas, low-temperature storage zones, baking workshops, etc.

3. Automatic Sensor High-Speed Doors

Features:

Contactless sensor activation to avoid cross-contamination

Can be intelligently integrated with production lines

Equipped with safety photoelectric protection devices

Fast operation speed up to 1.5-2m/s

Applicable Areas:Processing areas with frequent personnel access, logistics passages, etc.

III. Key Considerations for Selection

Material Selection Points

Prioritize non-toxic, odorless food-grade materials

Surface must withstand high-pressure washing and chemical disinfection

Avoid porous materials prone to bacterial growth

Cleaning and Maintenance Considerations

Choose fully detachable designs for thorough cleaning

Ensure there are no hard-to-clean dead corners

Electrical components must have sufficient waterproof rating

Performance Requirements

Motor protection rating should be at least IP54

Daily opening/closing cycles must meet actual needs

Ensure normal operation in low-temperature environments

Frequently Asked Questions

Q1: Do high-speed doors in food plants need daily cleaning?

A1: Depending on different hygiene level requirements, general production areas recommend thorough cleaning once a week, while high hygiene standard areas require daily cleaning. Choosing doors with smooth, seamless surfaces can significantly reduce cleaning difficulty.

Q2: How to prevent high-speed doors from becoming entry points for pests?

A2: It is recommended to choose door types with automatic bottom seals and install air curtain systems for dual protection. Also, ensure complete sealing around the door frame without gaps.

Q3: What should be noted when using high-speed doors in low-temperature environments?

A3: First, choose models suitable for low-temperature environments to ensure motors and control systems can operate normally in cold conditions. Pay special attention to sealing performance to avoid cold air loss. It's recommended to select door types with low-temperature self-heating function.

Recommended Products

up to date Automatic Door Accessories

- Precision High-Speed Door Drive Motor – Synchronous Servo with Worm Gear Reduction

- High Speed Door Fast Door Servo Motor Permanent Magnet AC-Synchronous Servo Motor with Worm Reductio

- High Speed Door Zippers Industrial Door Zippers

- High Speed Door Zippers Industrial Door Zippers

- 1.5KW Servo Motor & Control Box Set - High-Performance Drive System for Industrial Doors

- 0.75KW Servo Drive System for High-Speed Doors - Reliable & Energy-Efficient Solution

- 0.75KW Servo Motor Control Box Set – Efficient and Stable High-Speed Door Drive Solution

- AOK-AC123 Electric Curtain Wireless Remote / Wear-Resistant Acrylic Crystal Panel Remote

- Manufacturers Foot Pedal Activator Safety Beam Photocell Barrier Sensor For Medical Sliding Doors

- Safety photoelectric switch for high-speed door sensors

- Durable PVC Fast Rolling Door Fittings for Enhanced Security

- Automatic Repair of Zipper Door Plastic/Polymer Rails

- Smart Automatic Door Sensor for Fast Rolling Access Control

- Soft Fast Gate Control System 1.5kw Servo Motor and Control Box

- Automatic Access Control Square Surface Mount Infrared Non-Contact Switch

- Explosion-Proof Reinforced Self-Limiting Electric Heating Belt

- Explosion-Proof Shielded Self-Controlling Temperature Electric Heating Belt

- Heating Belt for Anti-Freezing, Heating and Heat Preservation of Cold Storage Doors

- 40W flame retardant explosion-proof self-limiting electric heating belt

- Safety Beam Sensor Use for Automatic Door