Key Differences Between UL-Certified and European Standard-Certified Fire Doors

1. Differences in Certification Standards and Testing Methods

UL certification follows U.S. standards (UL 10B/UL 10C), using a "time-temperature curve" test where furnace temperatures reach 538°C in 5 minutes and 927°C in 30 minutes, simulating flash-fire conditions. Certified doors are labeled with fire resistance durations (e.g., 20/45/60/90 minutes).

European certification complies with EN 1634-1, featuring a slower temperature rise (821°C in 30 minutes) but additional evaluations for insulation (unexposed surface ≤180°C) and radiation (≤15 kW/m² at 1m distance). For example, an EI60-rated door must withstand 60 minutes of fire while maintaining insulation.

Key Differences:

UL prioritizes structural integrity under extreme heat; European standards demand better insulation.

European certification requires 200,000 open-close cycle tests (EN 1191); UL has no mandatory durability test.

2. Material and Structural Parameters Compared

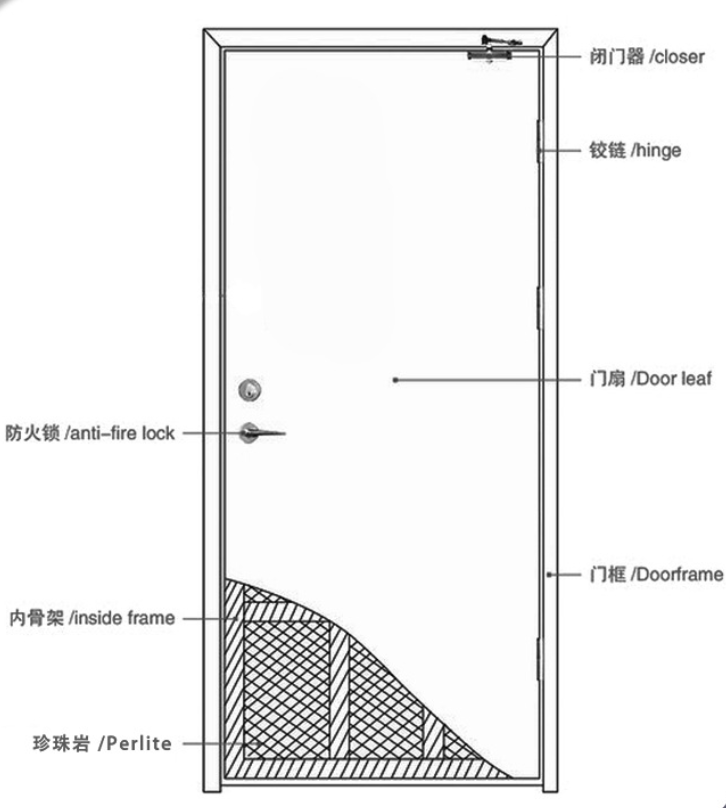

Typical UL-Certified Door Construction:

Core: Ceramic fiber or mineral wool (density ≥110kg/m³), strong fire resistance but weaker insulation.

Metal Edging: Steel frame ≥1.2mm thick, door leaf ≥0.8mm.

Seals: Intumescent graphite strips expanding 5–10x to block smoke.

European-Certified Door Design:

Core: Vermiculite boards or composite panels (density ≥150kg/m³), balancing fire resistance and insulation.

Hardware: Hinges and closers must meet EN 1634-3, with ≥80kg load capacity.

Gap Control: ≤3mm gaps, paired with dual-component seals (e.g., silicone + graphite).

Performance Comparison (60-Minute Rating Example):

| Parameter | UL-Certified Door | European EI60 Door |

|---|---|---|

| Max Unexposed Temp. | Not regulated | ≤180°C |

| Radiation Limit | Not tested | ≤15 kW/m² |

| Allowable Door Warping | ≤6mm | ≤3mm |

3. Applications and Regulatory Compliance

UL-Certified Doors Are Ideal For:

Mandatory in North America (e.g., NFPA 80 compliance).

High-risk environments like petrochemical plants/data centers (superior fire resistance).

European-Certified Doors Excel In:

EU, Middle East, and Southeast Asian projects (CPR Regulation compliance).

Public buildings (hospitals, schools) requiring strict insulation and smoke control.

Case Study:A Dubai hotel project needing both UL (for U.S. contractors) and European (local fire codes) certifications opted for dual-certified doors, increasing costs by 15–20% but avoiding retrofit expenses.

4. Selection Guide: Matching Certification to Needs

Regulations First: UL for the U.S., European for the EU; China’s GB standards partially align with European norms.

Performance Priorities: Choose European EI ratings for insulation/smoke control; UL for pure fire resistance.

Cost Considerations: European-certified doors cost 10–15% more due to additional testing.

FAQ: Frequently Asked Questions

Q1: Can UL and European certifications be used interchangeably?No. Regulations are region-specific—European authorities don’t accept UL as a CE mark substitute, and vice versa.

Q2: How do fire resistance ratings compare between standards?UL 60 minutes ≈ European EI30 (UL’s steeper test curve makes it more stringent).

Q3: Why does European certification impose stricter hardware requirements?European standards ensure doors remain operational during fires, mandating durable hinges/closers.

Q4: Are dual-certified doors superior?Yes, but costlier. Ideal for global projects (e.g., Middle East often requires UL + European certifications).

Q5: Does installation affect certification validity?Yes! Non-certified installers or substandard hardware (e.g., non-fire-rated locks) may void certification.

Recommended Products

up to dateSeychelles Automatic Door Accessories

- Manufacturers Foot Pedal Activator Safety Beam Photocell Barrier Sensor For Medical Sliding Doors

- Safety photoelectric switch for high-speed door sensors

- Durable PVC Fast Rolling Door Fittings for Enhanced Security

- Automatic Repair of Zipper Door Plastic/Polymer Rails

- Smart Automatic Door Sensor for Fast Rolling Access Control

- Soft Fast Gate Control System 1.5kw Servo Motor and Control Box

- Automatic Access Control Square Surface Mount Infrared Non-Contact Switch

- Explosion-Proof Reinforced Self-Limiting Electric Heating Belt

- Explosion-Proof Shielded Self-Controlling Temperature Electric Heating Belt

- Heating Belt for Anti-Freezing, Heating and Heat Preservation of Cold Storage Doors

- 40W flame retardant explosion-proof self-limiting electric heating belt

- High Speed Door Zippers Industrial Door Zippers

- Safety Beam Sensor Use for Automatic Door

- Wireless Hand Sensor Switch For Automatic Door

- Hospital Door Foot Sensor

- Automatic Sliding Door System Wireless Touch Press Switch

- Automatic Sliding Door IP65 Waterprooft Wireless Hand Press Switch

- Automatic Door Microwave Sensor

- Reflective Type Infrared Detector

- Automatic High Speed Door Infrared Radar Sensor CNB-204G