304 Stainless Steel Fire Door Frame: A Comprehensive Guide to the Core Skeleton of Safety Protection

1. 304 Stainless Steel: The "Safety DNA" of Fire Door Frames

304 stainless steel is widely used in fire door frames due to its unique material advantages:

Corrosion Resistance: Its alloy composition (18% chromium, 8% nickel) forms a passive oxide layer that blocks oxygen and moisture, preventing rust even in humid or high-temperature environments. Test data shows that 304 stainless steel can withstand over 5,000 hours in a neutral salt spray test without corrosion, far exceeding the 200-hour standard for ordinary carbon steel.

High-Temperature Stability: With a melting point of 1,400°C, it maintains structural integrity during fires (typically 800–1,200°C), preventing frame deformation that could compromise fire sealing.

Mechanical Strength: Tensile strength ≥520 MPa and yield strength ≥205 MPa ensure the frame can support door weight and impact loads without warping over time.

Why Choose 304 Over 201 Stainless Steel?

201 stainless steel contains only 1–3% nickel, making it prone to rust spots in humid conditions. In contrast, 304 stainless steel’s 8% nickel content improves corrosion resistance by 3x, making it ideal for hospitals, kitchens, basements, and other moisture-prone areas.

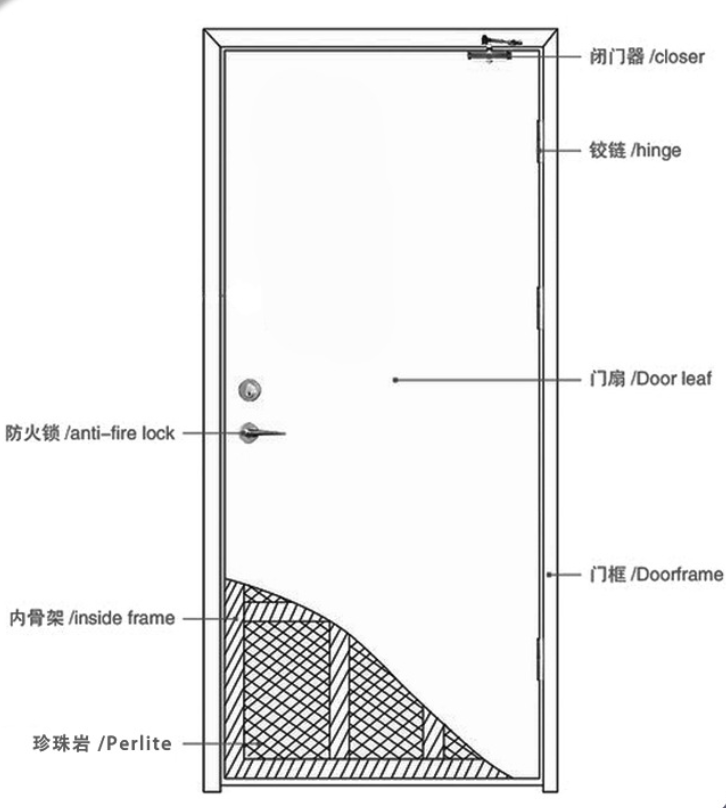

2. Structural Composition of a 304 Stainless Steel Fire Door Frame

A complete frame system consists of three key components working together to ensure fire resistance, sealing, and load-bearing performance:

1. Door Frame: The "Load-Bearing Skeleton"

Material: Made from 1.2–2.0 mm thick 304 stainless steel sheets, cold-formed into a U-shape for enhanced rigidity.

Key Features:

Sealing Groove: A 5–8 mm deep groove holds an intumescent fire seal (expands 3–5x when exposed to heat), blocking smoke and flames.

Mounting Holes: Pre-drilled M10 expansion bolt holes spaced ≤600 mm apart ensure secure wall attachment, meeting GB/T 13685-2009 wind resistance standards (withstands 1.5 kPa pressure).

2. Internal Reinforcement: The "Support Core"

Structure: Welded 304 stainless steel square tubes (50×30 mm or 40×20 mm, 1.0–1.5 mm wall thickness) form a grid or rectangular support.

Function: Enhances rigidity, preventing door sagging. Tests show reinforced frames support 80 kg/m² vs. 30 kg/m² for non-reinforced frames.

3. Fireproof Insulation: The "Thermal Barrier"

Materials: Perlite board (300–400 kg/m³ density) or fire-resistant rock wool (120–150 kg/m³) fills the space between the frame and outer panel.

Performance: Per GB 12955-2015 (Fire Door Standard), insulation must have a thermal conductivity ≤0.04 W/(m·K), keeping frame surface temperature ≤180°C during a 1-hour fire (Class A fire doors).

3. Key Parameters: The "Hard Metrics" of Frame Performance

When selecting a 304 stainless steel fire door frame, consider these critical specifications:

| Parameter | Requirement | Significance |

|---|---|---|

| Material Purity | 304 Stainless (Cr≥18%, Ni≥8%) | Ensures corrosion & heat resistance |

| Thickness | Frame: 1.5–2.0 mm, Reinforcement: 1.0–1.5 mm | Affects load-bearing & deformation resistance |

| Fire Rating | Class A (≥1.5h), B (≥1.0h), C (≥0.5h) | Determines fire resistance duration |

| Sealing | Intumescent seal expansion ≥300% | Blocks smoke and flames effectively |

| Salt Spray Test | ≥5,000 hours without rust | Validates long-term corrosion resistance |

4. Applications: Where 304 Stainless Steel Frames Are Essential

These high-demand environments benefit from 304 stainless steel’s fireproof + durable combination:

1. Medical Facilities (Hospitals, Labs)

Needs: Hygiene, moisture resistance, easy cleaning.

Example: A hospital operating room using 304 frames showed no rust after 5 years, passing hygiene tests (<10 CFU/cm² bacterial count).

2. High-Rise Buildings (Residential, Offices)

Requirement: Fire safety for evacuation routes.

Regulation: Per GB 50016, buildings >54 m tall require Class A fire doors (≥1.5h resistance).

3. Humid Areas (Underground Parking, Kitchens)

Advantage: 304 stainless steel outperforms carbon steel—e.g., a parking garage reduced frame failures from 20% to <1% annually.

4. Chemical/Food Processing Plants

Compliance: Resists acids, alkalis, and food contact, meeting FDA food-grade material standards.

5. Frequently Asked Questions (FAQ)

1. How to verify genuine 304 stainless steel?

Test: Use a stainless steel testing solution (304 stays unchanged; 201 turns red).

Certification: Request a material test report (Cr≥18%, Ni≥8%).

2. Does a fire door frame need maintenance?

Routine Care: Clean surfaces every 6 months; check seals for cracks (replace if damaged).

Humid Areas: Apply stainless steel protector annually to extend lifespan.

3. Does a 304 frame affect door operation?

No: Precision hinges (e.g., 304 stainless steel, 80 kg load capacity) and 3–4 mm door gaps ensure smooth operation (<80N opening force, per GB 12955).

Conclusion: A 304 stainless steel fire door frame is more than just a structural element—it’s a critical fire safety barrier. Its corrosion resistance, strength, and fireproof stability make it the optimal choice for modern construction. When selecting a frame, prioritize material quality, thickness, and fire rating to ensure long-lasting protection. Invest in 304 stainless steel for durability and safety that stands the test of time.

Recommended Products

up to dateSeychelles Automatic Door Accessories

- Manufacturers Foot Pedal Activator Safety Beam Photocell Barrier Sensor For Medical Sliding Doors

- Safety photoelectric switch for high-speed door sensors

- Durable PVC Fast Rolling Door Fittings for Enhanced Security

- Automatic Repair of Zipper Door Plastic/Polymer Rails

- Smart Automatic Door Sensor for Fast Rolling Access Control

- Soft Fast Gate Control System 1.5kw Servo Motor and Control Box

- Automatic Access Control Square Surface Mount Infrared Non-Contact Switch

- Explosion-Proof Reinforced Self-Limiting Electric Heating Belt

- Explosion-Proof Shielded Self-Controlling Temperature Electric Heating Belt

- Heating Belt for Anti-Freezing, Heating and Heat Preservation of Cold Storage Doors

- 40W flame retardant explosion-proof self-limiting electric heating belt

- High Speed Door Zippers Industrial Door Zippers

- Safety Beam Sensor Use for Automatic Door

- Wireless Hand Sensor Switch For Automatic Door

- Hospital Door Foot Sensor

- Automatic Sliding Door System Wireless Touch Press Switch

- Automatic Sliding Door IP65 Waterprooft Wireless Hand Press Switch

- Automatic Door Microwave Sensor

- Reflective Type Infrared Detector

- Automatic High Speed Door Infrared Radar Sensor CNB-204G