Differences in Motor Placement for Zipper Fast Doors: A Comprehensive Guide from Blueprints to Real-

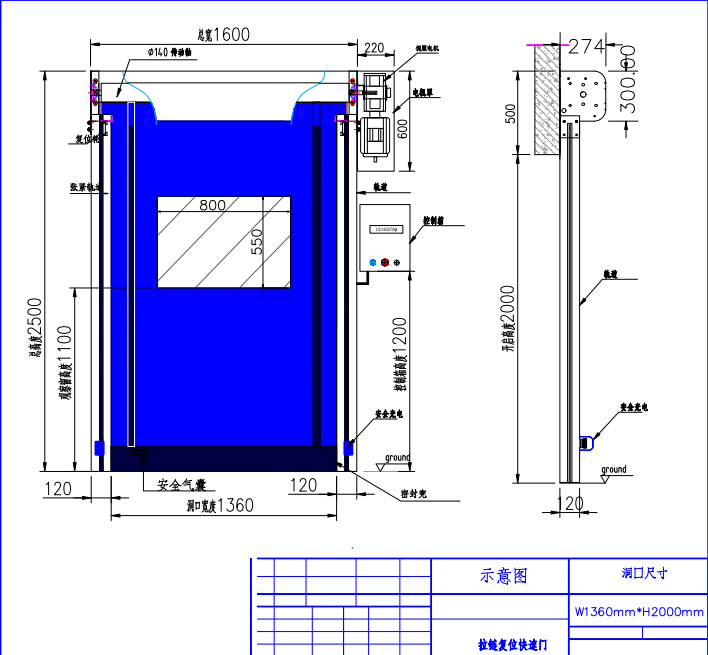

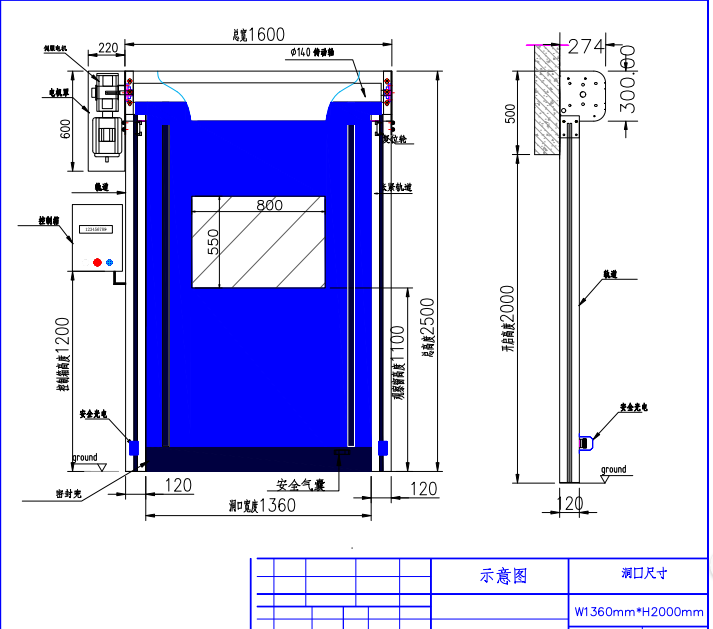

1. Two Core Motor Layouts: Visual Differences in Blueprints

Space Occupancy:

A left-mounted motor (left blueprint) requires a 600mm×220mm vertical space reserve on the door’s left side, while a right-mounted motor (right blueprint) occupies an equivalent area on the right. This directly dictates the required clearance between the door and adjacent equipment/walls.

Counterweight Balance:

Zipper fast doors rely on counterweights on both sides to maintain stable operation. Switching the motor between left and right requires a corresponding adjustment of the counterweight’s position (counterweights are on the right in the left blueprint, left in the right blueprint). Failure to adjust this can cause door tilting or jamming during operation.

2. Parameter Variations: Performance Impacts from Blueprints to Reality

Operating Noise:

If the motor is placed near a personnel area (e.g., a walkway), noise levels increase by 3-5 decibels (based on a 75dB baseline). Mounting the motor on the side away from personnel (e.g., the warehouse interior in the right blueprint) reduces noise exposure and minimizes workplace disruption.

Maintenance Space:

The motor side requires a minimum 800mm×1000mm operating area (labeled “maintenance zone” in the blueprints). Mounting the motor on the wall-adjacent side frees up the opposite side for storage, adding approximately 1.2㎡ of usable space.

Energy Consumption:

Each additional meter of wiring increases power loss by ~0.5% (for a 3kW motor). For a 1.36m-wide door, the wiring length difference between left and right mounting translates to ~20-30 kWh of annual energy savings (based on 100 daily cycles), reducing long-term electricity costs.

Application Scenarios:

Left-mounted motor: Ideal when the door’s right side connects to conveyors, racks, or other equipment—avoids motor interference with equipment layout.

Right-mounted motor: Suitable when the door’s left side is a fire escape or emergency exit. Prevents the motor from blocking evacuation paths, complying with the Code for Fire Protection Design of Buildings requirement for “evacuation path clear width ≥1.2m.”

3. Why Motor Placement Matters: Practical Value in Real Scenarios

Space Compatibility:

In narrow workshop aisles (3m wide), mounting the motor on the non-aisle side prevents collisions with forklifts or carts, reducing equipment damage by ~15%.

Maintenance Efficiency:

Mounting the motor near the door’s control panel eliminates the need to walk around the door during repairs, cutting single-maintenance time by 20-30 minutes—critical for high-throughput logistics warehouses (over 200 daily cycles).

Safety Risk Reduction:

In explosion-proof chemical workshops, mounting the motor away from hazardous areas reduces spark-related risks, aligning with the Code for Design of Electrical Installations in Explosive Atmospheres.

Frequently Asked Questions (FAQ)

1. Can the motor position be changed later?

2. Does motor placement affect door opening/closing speed?

3. For what door sizes is motor placement critical?

4. Is it better to mount the motor indoors or outdoors?

Recommended Products

up to dateMadagascan Automatic Door Accessories

- Manufacturers Foot Pedal Activator Safety Beam Photocell Barrier Sensor For Medical Sliding Doors

- Safety photoelectric switch for high-speed door sensors

- Durable PVC Fast Rolling Door Fittings for Enhanced Security

- Automatic Repair of Zipper Door Plastic/Polymer Rails

- Smart Automatic Door Sensor for Fast Rolling Access Control

- Soft Fast Gate Control System 1.5kw Servo Motor and Control Box

- Automatic Access Control Square Surface Mount Infrared Non-Contact Switch

- Explosion-Proof Reinforced Self-Limiting Electric Heating Belt

- Explosion-Proof Shielded Self-Controlling Temperature Electric Heating Belt

- Heating Belt for Anti-Freezing, Heating and Heat Preservation of Cold Storage Doors

- 40W flame retardant explosion-proof self-limiting electric heating belt

- High Speed Door Zippers Industrial Door Zippers

- Safety Beam Sensor Use for Automatic Door

- Wireless Hand Sensor Switch For Automatic Door

- Hospital Door Foot Sensor

- Automatic Sliding Door System Wireless Touch Press Switch

- Automatic Sliding Door IP65 Waterprooft Wireless Hand Press Switch

- Automatic Door Microwave Sensor

- Reflective Type Infrared Detector

- Automatic High Speed Door Infrared Radar Sensor CNB-204G