Roller Shutter Components: A Comprehensive Guide to Guide Rails, Bottom Bars, and Color Steel Slats

I. Guide Rails: The "Skeletal Track" Ensuring Operational Stability

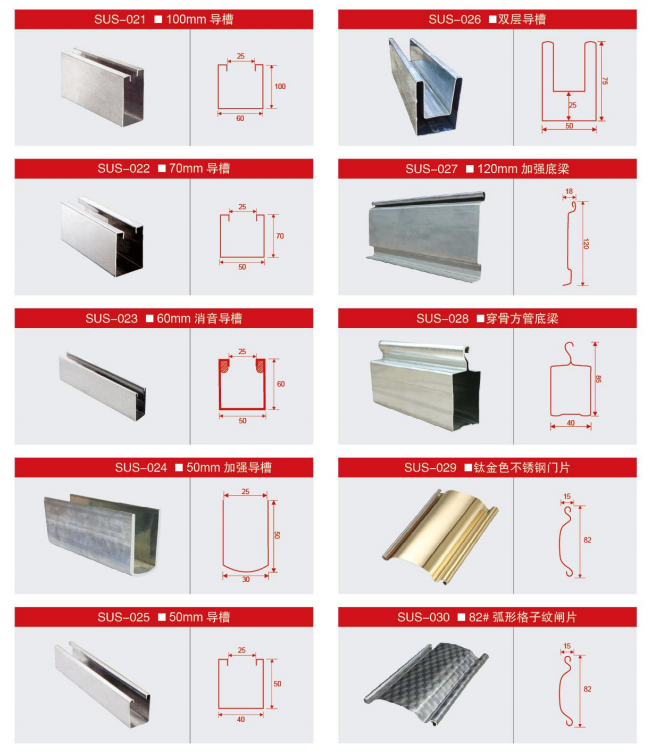

Guide rails are the tracks for slat movement, with material, thickness, and structure directly impacting wind resistance and smooth operation. Common widths include 100mm, 70mm, and 60mm, designed to match slat thickness and opening width.

1. 100mm Heavy-Duty Guide Rail (SUS-021): Industrial-Grade Wind Resistance

Structural Parameters: 100mm width, 60mm height, ≥1.5mm thickness, cold-rolled steel integrated molding with wear-resistant nylon strips (friction coefficient ≤0.3).

Performance Advantages: Withstands 12 wind force grades (wind load ≥0.75kPa), vertical load capacity ≥500kg. Ideal for openings ≥6m wide in factories and port warehouses.

Application Case: Paired with 120# thick slats in typhoon-prone regions (e.g., Guangdong, Fujian), reducing deformation risk by 40% compared to standard rails.

2. 70mm Standard Guide Rail (SUS-022): Commercial Workhorse

Structural Parameters: 70mm width, 50mm height, 1.2mm thickness, electrophoretic rust-resistant coating (salt spray test ≥500 hours).

Performance Advantages: Compatible with 76#/82# slats, operating noise ≤55dB (equivalent to normal conversation), 30% faster installation. Suits small-to-medium shops and underground garages.

Real-World Example: A supermarket with a 4.5m-wide opening using 70mm rails + 82# curved slats achieved 20 daily operations with zero jamming over 5 years, cutting maintenance costs by 60%.

3. 60mm Silent Guide Rail (SUS-023): Premium Quiet Solution

Structural Parameters: 60mm width, 50mm height, 1.0mm thickness, built-in shock-absorbing rubber strips and ball bearing guides.

Key Benefits: Ultra-low noise ≤45dB (library-grade), 20% faster lifting speed (0.2m/s). Perfect for hospitals, office buildings, and high-end malls.

Technical Innovation: U-shaped reinforcing ribs boost anti-twist strength by 25%, preventing track deformation from long-term use.

II. Bottom Bars: The "Load-Bearing Foundation" for Safety and Sealing

Bottom bars support slat weight, resist impacts, and enhance sealing/security. Common types include reinforced bars, tube-in-square bars, and split bars, tailored to slat weight and usage scenarios.

1. 120mm Reinforced Bottom Bar (SUS-027): Heavy-Duty Essential

Specifications: Length ≤6m, cross-section 18mm×80mm, Q235 galvanized steel (yield strength ≥235MPa), with anti-detachment devices at both ends.

Load Capacity: Supports ≥300kg slats. Impact test (100kg weight dropped from 1m) shows no plastic deformation when paired with 120# slats.

Ideal Applications: Industrial workshops and logistics warehouses with frequent forklift traffic, reducing sagging from collisions.

2. Tube-In-Square Bottom Bar (SUS-028): Lightweight Security

Structural Features: 40mm×60mm square tube with internal Φ25mm steel reinforcement, 3mm rubber seal (IP54 waterproof rating).

Performance Data: Bending strength ≥200MPa, 15% lighter than reinforced bars. Suits 82# slats (slat weight ≤150kg) in commercial storefronts.

Anti-Theft Edge: Concrete-filled (1:2:3 mix) core resists prying for ≥10 minutes, meeting GA/T 73-2015 "Mechanical Anti-Theft Locks" Class B standards.

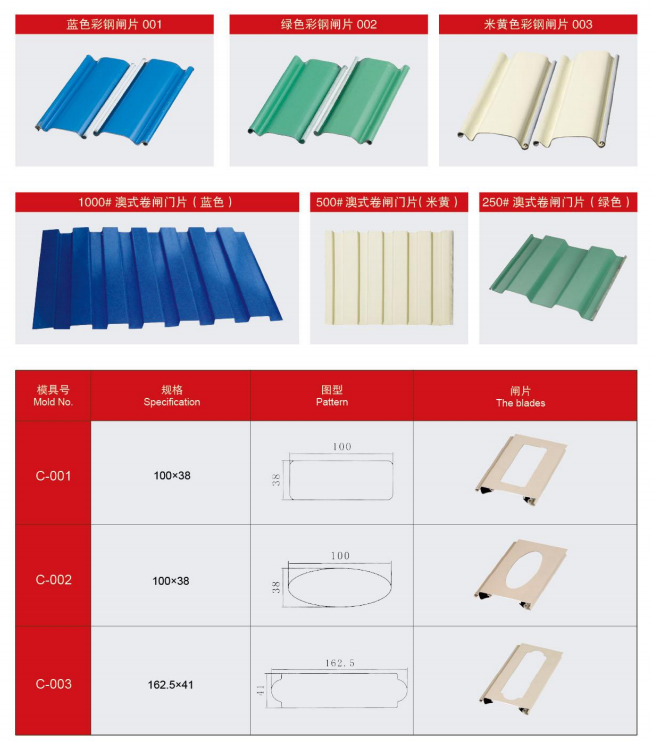

3. Split Bottom Bars (Series C): Customized Solutions

Model Variations: C-001 (100×38mm), C-002 (100×38mm with oval holes), C-003 (162.5×41mm), available in galvanized steel or aluminum.

Functional Differentiation:

C-002 (oval holes): 10% weight reduction with improved slat engagement, ideal for fast-acting automatic shutters.

C-003 (wider profile): 20% larger ground contact area enhances sealing, used in cold storage and cleanrooms with strict temperature/dust control.

III. Color Steel Slats: Cost-Effective, Aesthetic, and Practical

Color steel slats, made of pre-painted steel sheets via roll forming, offer low cost, vibrant colors (blue, green, beige), and easy installation. They excel in temporary buildings, shop renovations, and budget projects.

1. 250# Australian-Style Slats (Green/Beige): Lightweight Temporary Use

Specifications: 0.3mm thickness, 15mm wave height, 250mm, ≤5kg/㎡ weight, PVDF coating (10-year weather resistance).

Limitations: Wind resistance only 6 grades (≤0.3kPa), suitable for ≤3m openings with low usage frequency (e.g., construction site warehouses, simple carports).

Cost Advantage: 40% lower material cost than galvanized steel slats, 50% faster installation—ideal for short-term budget projects.

2. 500# Australian-Style Slats (Beige): Commercial Standard

Structural Upgrade: 0.4mm thickness, 20mm wave height, middle reinforcement rib boosts deformation resistance by 30%, customizable colors (RAL color chart options).

Application Fit: Small shops and convenience stores. Paired with 70mm guide rails, handles ≤10 daily operations; surface stains wipe clean with water.

Case Comparison: A community supermarket using 500# beige slats showed no significant fading after 3 years, with maintenance costs 1/5 of stainless steel slats.

3. 1000# Australian-Style Slats (Blue): Industrial-Grade Color Steel

High-Strength Design: 0.5mm double-layer with 5mm foam core, thermal insulation coefficient ≤0.3W/(m·K), 8 wind resistance grades.

Functional Add-Ons: Optional polycarbonate (85% light transmission) and ventilation holes (φ10mm, 15% airflow rate), suitable for light workshops and logistics hubs.

IV. Component Matching Logic: The Slat-Rail-Bar Selection Formula

Bottom Bar vs. Slat Weight:

<100kg → Tube-in-square bar (SUS-028);

100–300kg → 120mm reinforced bar (SUS-027);

- >300kg → Custom twin-bar (load calculation required).

Guide Rail vs. Opening Width:

<4m → 60mm silent rail (SUS-023);

4–6m → 70mm standard rail (SUS-022);

- >6m → 100mm heavy-duty rail (SUS-021).

Material vs. Environment:

Coastal/humid areas → Stainless steel rails + 304 stainless steel bars;

Dry inland areas → Galvanized steel rails + galvanized bars;

Temporary/short-term use → Color steel slats + aluminum rails.

V. Frequently Asked Questions (FAQ)

Q1: What happens if the gap between guide rails and slats is too large or small?

A: Excessive gaps (>5mm) cause shutter wobble and reduce wind resistance; tight gaps (<2mm) risk jamming due to thermal expansion or installation errors. The optimal gap is 3±0.5mm. Use a level to ensure rail verticality (deviation ≤1mm/m) during installation.

Q2: How to estimate the lifespan of color steel vs. galvanized steel slats?

A: Color steel lifespan depends on coating: polyester paint (5–8 years), PVDF coating (10–15 years). Galvanized steel lifespan depends on zinc layer thickness: 80g/㎡ (10–15 years), 120g/㎡ (20+ years). Prioritize galvanized steel in coastal areas.

Q3: How to replace老化 bottom bar seals?

A: Pry out old seals with a flat screwdriver, clean the groove, apply rubber adhesive (e.g., 3M 4799), then press new EPDM seals (-40℃~120℃ tolerance) into the groove for 10 minutes. Replace every 3–5 years.

Q4: Are silent guide rails always better than standard rails?

A: No. Silent rails (SUS-023) reduce noise via rubber strips but cost 20% more and may harden in sub-10℃ temperatures. They suit noise-sensitive areas (hospitals), while standard rails are more economical for industrial settings with high noise tolerance.

Q5: How to prevent cracking at guide rail-wall joints?

A: Install M10×100mm expansion bolts every 50cm (tensile strength ≥30kN). For openings >5m, add 45° steel (Q235) bracing at mid-rail. Use silicone sealant to fill gaps, absorbing vibration stress.

This guide equips readers with technical insights and selection logic for roller shutter components. For optimal results, consult manufacturers for load calculations and custom designs, ensuring long-term system stability.

Recommended Products

up to dateSeychelles Automatic Door Accessories

- Manufacturers Foot Pedal Activator Safety Beam Photocell Barrier Sensor For Medical Sliding Doors

- Safety photoelectric switch for high-speed door sensors

- Durable PVC Fast Rolling Door Fittings for Enhanced Security

- Automatic Repair of Zipper Door Plastic/Polymer Rails

- Smart Automatic Door Sensor for Fast Rolling Access Control

- Soft Fast Gate Control System 1.5kw Servo Motor and Control Box

- Automatic Access Control Square Surface Mount Infrared Non-Contact Switch

- Explosion-Proof Reinforced Self-Limiting Electric Heating Belt

- Explosion-Proof Shielded Self-Controlling Temperature Electric Heating Belt

- Heating Belt for Anti-Freezing, Heating and Heat Preservation of Cold Storage Doors

- 40W flame retardant explosion-proof self-limiting electric heating belt

- High Speed Door Zippers Industrial Door Zippers

- Safety Beam Sensor Use for Automatic Door

- Wireless Hand Sensor Switch For Automatic Door

- Hospital Door Foot Sensor

- Automatic Sliding Door System Wireless Touch Press Switch

- Automatic Sliding Door IP65 Waterprooft Wireless Hand Press Switch

- Automatic Door Microwave Sensor

- Reflective Type Infrared Detector

- Automatic High Speed Door Infrared Radar Sensor CNB-204G