Common Types of Roller Shutter Door Slats

1. Aluminum Alloy Slats

Aluminum alloy slats are one of the most common types of roller shutter slats, favored for their lightweight, corrosion resistance, and aesthetic appeal.

Key Parameters

Thickness: Typically 0.8mm–1.2mm, with high-end commercial doors reaching 1.5mm.

Surface Treatment: Anodized, powder-coated, or fluorocarbon-coated to enhance weather resistance and UV protection.

Color Options: Customizable colors to match various architectural styles.

Advantages

Lightweight: Easier to roll compared to steel slats, reducing motor load and extending lifespan.

Corrosion Resistance: Suitable for coastal or high-humidity areas, resistant to rust.

Aesthetic Appeal: Smooth surface complements modern architectural designs.

Applications

Shopfronts

Residential garages

Office building exteriors

2. Stainless Steel Slats

Stainless steel slats are known for their high strength and corrosion resistance, available in 201, 304, and 316 stainless steel to suit different environmental needs.

Key Parameters

Material:

201 Stainless Steel: Higher manganese content, moderate corrosion resistance, suitable for dry inland areas.

304 Stainless Steel: Contains 18% chromium and 8% nickel, offering good corrosion resistance for general use.

316 Stainless Steel: Includes molybdenum, providing excellent corrosion resistance, especially for high-salinity environments.

Thickness: 0.6mm–1.5mm, with industrial-grade slats up to 2.0mm.

Surface Treatment: Brushed, mirror, or sandblasted finishes for enhanced aesthetics.

Advantages Comparison

| Material | Corrosion Resistance | Cost | Suitable Environment |

|---|---|---|---|

| 201 | Moderate | Lowest | Dry regions |

| 304 | Good | Medium | Most regions |

| 316 | Excellent | Highest | Coastal/industrial areas |

Applications

201 Stainless Steel: Standard shops, temporary structures

304 Stainless Steel: Banks, shopping malls, commercial spaces

316 Stainless Steel: Chemical plants, coastal buildings

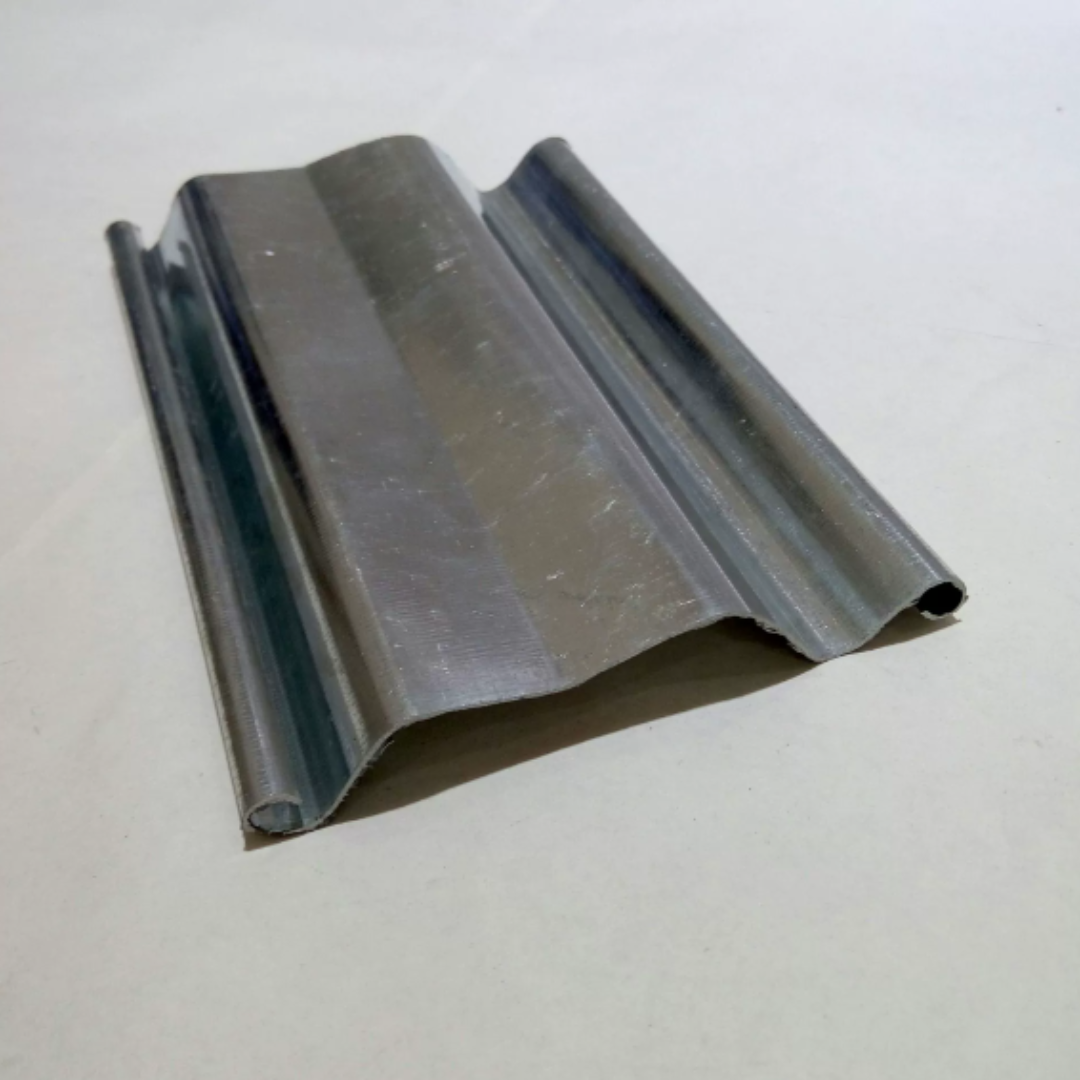

3. Color Steel Slats (Galvanized Steel Slats)

Color steel slats are made from galvanized steel with a colored coating, offering a balance of affordability and durability.

Key Parameters

Base Material: Galvanized steel (zinc layer ≥20μm).

Coating: Polyester (PE), fluorocarbon (PVDF), etc., affecting weather resistance.

Thickness: 0.3mm–0.8mm, with industrial doors up to 1.0mm.

Advantages

Cost-Effective: More economical than aluminum or stainless steel.

Moderate Strength: Suitable for basic security needs.

Color Variety: Customizable colors through coating.

Applications

Warehouses, logistics centers

Small shops

Temporary construction barriers

4. Transparent/Semi-Transparent Slats (Polycarbonate or PVC)

These slats use light-transmitting materials, ideal for spaces requiring natural light or display purposes.

Key Parameters

Material: Polycarbonate (PC) or PVC; PC offers better impact resistance.

Light Transmission: 70%–90%, with frosted options for privacy.

Thickness: 1.5mm–3.0mm; PC slats are more impact-resistant.

Advantages

Natural Lighting: Reduces indoor lighting needs, saving energy.

Lightweight: Suitable for manual roller shutters.

UV Resistance: PC material prevents UV degradation.

Applications

Storefront displays

Sunrooms

Parking lot entrances

5. Fireproof Slats (Composite Metal + Fireproof Core)

Fireproof slats feature a multi-layer structure with fire-resistant fillers to achieve flame retardancy.

Key Parameters

Fire Rating: Class A (non-combustible), Class B (flame-retardant), with 30–120 minutes of fire resistance.

Structure: Double-layer steel with rock wool or aluminum silicate fiber filling.

Thickness: 40mm–80mm; thicker slats offer better fire resistance.

Advantages

Fire Resistance: Slows fire spread, enhancing safety.

Sound and Heat Insulation: Filler layers reduce noise and heat transfer.

Applications

Chemical plants, gas stations

High-rise building fire compartments

Data centers

6. Silent Slats (Noise-Reducing Structure)

Silent slats incorporate special designs (e.g., rubber seals, multi-layer composites) to minimize operational noise.

Key Parameters

Noise Level: ≤50 dB (standard slats: 60–70 dB).

Structure: Nylon guide rollers and noise-absorbing strips between slats.

Advantages

Quiet Operation: Ideal for residential areas or nighttime use.

Reduced Wear: Noise-reducing design decreases rail friction, extending lifespan.

Applications

Residential garages

Hospitals, schools

High-end homes

FAQ (Frequently Asked Questions)

Q1: How to choose between 201, 304, and 316 stainless steel slats?

A: 201 is budget-friendly for dry inland areas; 304 suits most general environments; 316 is designed for high-corrosion areas like coastal or industrial zones.

Q2: How to select the right thickness for roller shutter slats?

A: Residential: 0.8mm–1.2mm; commercial: ≥1.2mm; industrial: ≥1.5mm.

Q3: Are transparent slats secure?

A: Polycarbonate (PC) is impact-resistant but less secure than metal slats; suitable for low-risk areas.

Q4: Do fireproof slats really work?

A: Yes, certified fireproof slats can resist flames for 30–120 minutes, depending on the fire rating.

Q5: How to reduce roller shutter noise?

A: Opt for silent slats or install nylon guide rollers and lubricate the chain regularly.

Recommended Products

up to dateNorway Automatic Door Accessories

- Manufacturers Foot Pedal Activator Safety Beam Photocell Barrier Sensor For Medical Sliding Doors

- Safety photoelectric switch for high-speed door sensors

- Durable PVC Fast Rolling Door Fittings for Enhanced Security

- Automatic Repair of Zipper Door Plastic/Polymer Rails

- Smart Automatic Door Sensor for Fast Rolling Access Control

- Soft Fast Gate Control System 1.5kw Servo Motor and Control Box

- Automatic Access Control Square Surface Mount Infrared Non-Contact Switch

- Explosion-Proof Reinforced Self-Limiting Electric Heating Belt

- Explosion-Proof Shielded Self-Controlling Temperature Electric Heating Belt

- Heating Belt for Anti-Freezing, Heating and Heat Preservation of Cold Storage Doors

- 40W flame retardant explosion-proof self-limiting electric heating belt

- High Speed Door Zippers Industrial Door Zippers

- Safety Beam Sensor Use for Automatic Door

- Wireless Hand Sensor Switch For Automatic Door

- Hospital Door Foot Sensor

- Automatic Sliding Door System Wireless Touch Press Switch

- Automatic Sliding Door IP65 Waterprooft Wireless Hand Press Switch

- Automatic Door Microwave Sensor

- Reflective Type Infrared Detector

- Automatic High Speed Door Infrared Radar Sensor CNB-204G