Galvanized Steel/Stainless Steel Shutter Slat 1: A Comprehensive Guide to Types and Applications

I. Classification Logic and Key Parameters of Shutter Slats

Shutter slats are classified through three key dimensions, with distinct differences in safety, durability, and aesthetics across types.

1. Materials: Galvanized Steel vs. Stainless Steel

Galvanized Steel Slats: Cold-rolled steel sheets with zinc coating, offering low cost and good rust resistance. Ideal for general industrial and commercial settings (e.g., warehouses, retail stores).

Stainless Steel Slats: Made of 304/201 stainless steel, providing superior corrosion resistance and a sleek surface. Suitable for high-end commercial spaces, food processing plants, and coastal humid environments.

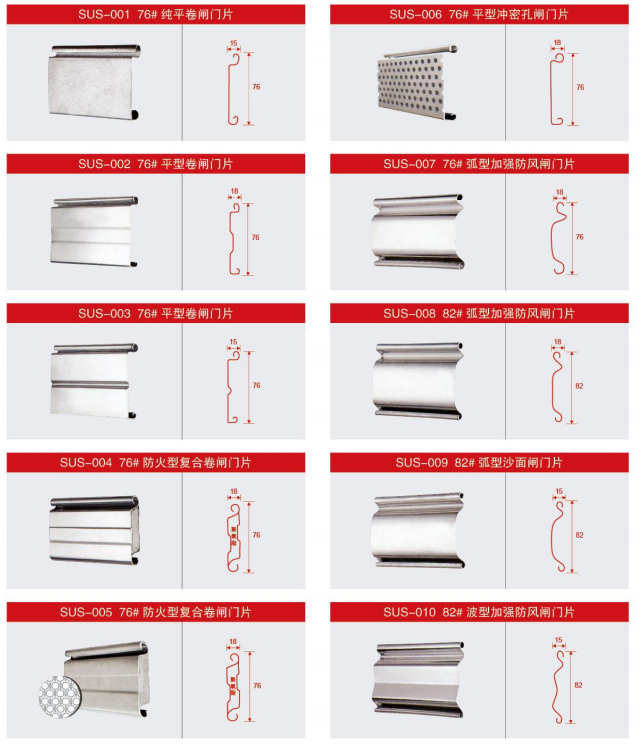

2. Structural Specifications: Named by "Width + Function"

Slat specifications are primarily identified by width (mm), such as 76#, 82#, and 120#, where the number represents the slat’s expanded width. They are further classified by structural design (e.g., flat, curved, perforated) and functionality (e.g., fireproof, wind-resistant, anti-theft), e.g., "82# Curved Reinforced Wind-Resistant Slat".

3. Key Technical Parameters

Thickness: Common range 0.3–1.2mm. Thicker slats enhance load-bearing capacity and impact resistance (e.g., 120# slats, 0.8–1.2mm thick, are used for large factories).

Tensile Strength: Galvanized steel: ~235–345MPa; Stainless steel: ~520MPa. Higher strength reduces deformation risks.

Wind Resistance: Curved slats (e.g., 120# curved reinforced type) withstand up to 12 wind force grades, outperforming flat slats (8–10 grades).

II. In-Depth Analysis of Mainstream Slat Types and Applications

1. 76# Series: Lightweight & Economical for Small-Medium Openings

76# slats (76mm width, 0.3–0.5mm thickness) are lightweight and easy to install, suitable for openings ≤4 meters wide.

Typical Types & Parameters:

SUS-001 Flat Slat: Smooth, non-perforated design for general shops and garages. Service life: 5–8 years.

SUS-006 Perforated Flat Slat: Evenly distributed φ5mm holes balance ventilation (15–20% airflow rate) and security. Ideal for markets and ventilated warehouses.

SUS-004 Fireproof Composite Slat: Double-layer structure with fire-resistant cotton, ≥1.5-hour fire resistance (compliant with GB 14102-2005). Used in fire exits and electrical rooms.

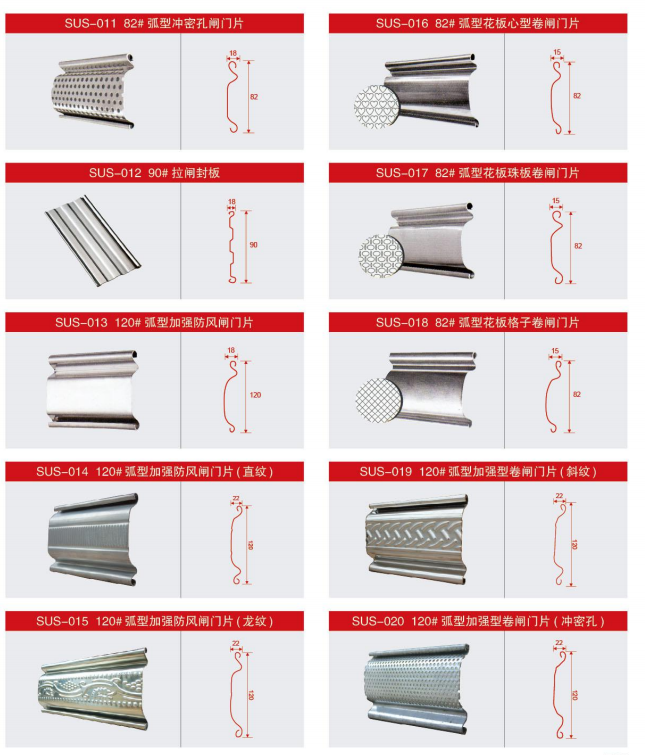

2. 82# Series: Balanced Performance & Cost for Commercial Spaces

82# slats (82mm width, 0.4–0.7mm thickness) offer better load-bearing and wind resistance than 76# slats, covering over 80% of commercial storefronts.

Typical Types & Parameters:

SUS-008 Curved Reinforced Wind-Resistant Slat: Curved profile with reinforcing ribs, ≥10 wind force resistance. Reduces deformation by 40% vs. flat slats, suitable for high-rise commercial buildings and coastal shops.

SUS-016 Curved Patterned Slat: Embossed surface (e.g., diamond, chrysanthemum patterns) enhances aesthetics and strength. Used in brand boutiques and supermarkets.

SUS-009 Curved Sandblasted Slat: Matte, fingerprint-resistant finish for easy cleaning. Meets GMP standards for food processing plants and cleanrooms.

3. 120# Series: Heavy-Duty Industrial Grade for Large-Span Openings

120# slats (120mm width, 0.8–1.2mm thickness) weigh 15–20kg/㎡, designed for openings ≥6 meters wide (e.g., factories, logistics warehouses).

Typical Types & Parameters:

SUS-013 120# Curved Reinforced Wind-Resistant Slat: Wave-shaped cross-section with double-layer folding structure, withstands 12 wind force grades (wind pressure ≥0.7kPa). Used in port warehouses and large workshops.

SUS-019 Diagonal Pattern Reinforced Slat: Diagonal纹路 boosts tensile strength by 25%, with 15J impact resistance (GB/T 228 standard). Suitable for logistics channels with frequent forklift traffic.

SUS-020 Perforated Slat: Rectangular holes (10×30mm) provide 30% airflow rate. Paired with anti-theft grilles for ventilated machinery rooms.

III. Four-Step Slat Selection Guide

Scenario Positioning: Choose 82# decorative slats for commercial facades, 120# heavy-duty slats for industrial plants, and stainless steel for humid environments.

Performance Prioritization:

Anti-theft: Select thick slats (≥0.8mm) + anti-pry locks.

Fire safety: Choose certified fireproof composite slats.

Ventilation: Opt for slats with 15–30% perforation rate.

Cost Evaluation: Galvanized steel slats have lower upfront costs but a 5–10 year shorter lifespan than stainless steel, making stainless steel more cost-effective long-term.

Installation Compatibility: Slat thickness must match roller bearing capacity (e.g., 120# slats require ≥80mm diameter rollers).

IV. Frequently Asked Questions (FAQ)

Q1: How to choose between galvanized steel and stainless steel slats?

A: Galvanized steel is ideal for budget-constrained, dry environments (e.g., workshops). Stainless steel suits humid areas (coastal regions, food plants) and high-end commercial spaces (luxury stores). In northern China, galvanized steel offers better value; in southern rainy regions, stainless steel reduces rust-related maintenance.

Q2: Is thicker always better for slat thickness?

A: No. For example, a 3-meter-wide storefront functions well with 0.5mm thick 82# slats. Overly thick slats (e.g., 1.2mm) may overload rollers and cause motor failures. Consider opening width and usage frequency.

Q3: How does surface treatment affect performance?

A: Galvanized steel slats may use powder coating (custom colors) or baking paint (enhanced weather resistance). Stainless steel slats can be brushed or mirrored. Powder-coated slats offer 2–3 years better corrosion resistance than standard galvanized slats, suitable for outdoor use.

Q4: How to assess slat quality?

A: ① Measure thickness with calipers to avoid misrepresentation. ② Check welds for smoothness (no burrs or gaps). ③ Test operation: Slats should open/close smoothly without jamming, indicating sound structural design.

This guide clarifies slat types, parameters, and applications to help readers balance safety, economy, and compatibility. For optimal results, consult manufacturers for load calculations to ensure slats meet specific needs.

Recommended Products

up to dateMalta Automatic Door Accessories

- Manufacturers Foot Pedal Activator Safety Beam Photocell Barrier Sensor For Medical Sliding Doors

- Safety photoelectric switch for high-speed door sensors

- Durable PVC Fast Rolling Door Fittings for Enhanced Security

- Automatic Repair of Zipper Door Plastic/Polymer Rails

- Smart Automatic Door Sensor for Fast Rolling Access Control

- Soft Fast Gate Control System 1.5kw Servo Motor and Control Box

- Automatic Access Control Square Surface Mount Infrared Non-Contact Switch

- Explosion-Proof Reinforced Self-Limiting Electric Heating Belt

- Explosion-Proof Shielded Self-Controlling Temperature Electric Heating Belt

- Heating Belt for Anti-Freezing, Heating and Heat Preservation of Cold Storage Doors

- 40W flame retardant explosion-proof self-limiting electric heating belt

- High Speed Door Zippers Industrial Door Zippers

- Safety Beam Sensor Use for Automatic Door

- Wireless Hand Sensor Switch For Automatic Door

- Hospital Door Foot Sensor

- Automatic Sliding Door System Wireless Touch Press Switch

- Automatic Sliding Door IP65 Waterprooft Wireless Hand Press Switch

- Automatic Door Microwave Sensor

- Reflective Type Infrared Detector

- Automatic High Speed Door Infrared Radar Sensor CNB-204G