Roller Shutter Slat Types : Technical Characteristics, Specifications

I. Core Advantages of Aluminum Slats: Why They Outperform Steel Slats for Modern Architecture

Aluminum slats, made from 6063-T5 aluminum profiles via extrusion molding, offer three irreplaceable advantages over traditional steel slats:

1. Balanced Lightweight and High Rigidity

Density Advantage: Aluminum has a density of only 2.7g/cm³, 65% lighter than galvanized steel (7.85g/cm³). For example, an 85# double-layer four-rib slat weighs ~8kg/㎡, compared to 15kg/㎡ for a steel slat of the same size. This reduces motor load by 30% and extends equipment lifespan by 2–3 years.

Structural Reinforcement: "Hollow + reinforced rib" designs (e.g., 85# slats with 4 longitudinal ribs) achieve a bending strength of 180MPa, meeting GB/T 14436-2007 Aluminum and Aluminum Alloy Profiles standards, with wind resistance of 8–10 grades (wind load 0.5–0.6kPa).

2. All-Scenario Corrosion Resistance

Surface Treatment Technologies: Anodizing (film thickness ≥10μm), powder coating (60–80μm), and wood-grain transfer printing (weather resistance ≥1500 hours) all pass 500+ hours of salt spray testing. In coastal areas, they remain rust-free for 10 years, cutting maintenance costs by 70% compared to steel slats.

3. Customized Aesthetic Design

Colors and Textures: Supports over 200 RAL colors with 12 surface finishes (glossy, matte, wood-grain, copper-like). For example, AL-022 copper-like slats cost 60% less than solid copper slats and avoid oxidation-induced blackening.

II. Specifications and Performance Parameters of Mainstream Aluminum Slats

Aluminum slats are identified by width (mm) and rib count, ranging from 37# to 95# to suit diverse door sizes and functional needs. Below is a technical analysis of five key series:

1. 37#/50# Series: Lightweight Solutions for Small Openings

37# Double-Layer Single-Rib Slat (AL-001)

Parameters: 37mm width, 0.8mm thickness, hollow structure with single rib reinforcement, 4.5kg/㎡ weight. Ideal for openings ≤2.5m wide (e.g., convenience stores, storage rooms).

Advantages: Operates at ≤50dB noise, installable up to 3m height, and runs stably for 8 years with 30 daily operations.

50# Double-Layer Reverse-Roll Slat (AL-003/AL-006)

Parameters: 50mm width, 0.9mm thickness, reverse-roll design reduces installation space by 30%, 6kg/㎡ weight. AL-006 features wood-grain transfer printing.

Application Case: Installed in a community garage, it saved 0.5m³ of overhead space, improving vehicle access convenience.

2. 80#/85# Series: Workhorses for Commercial Scenarios

80# Double-Layer Three-Rib Slat (AL-009/AL-010)

Parameters: 80mm width, 1.0mm thickness, 3 reinforcing ribs, wind resistance grade 9 (0.55kPa), 7.5kg/㎡ weight. Fits 3–5m wide openings.

Function Extension: Optional single-layer perforated model (AL-008, 15% perforation rate) balances ventilation and security for markets and flower shops.

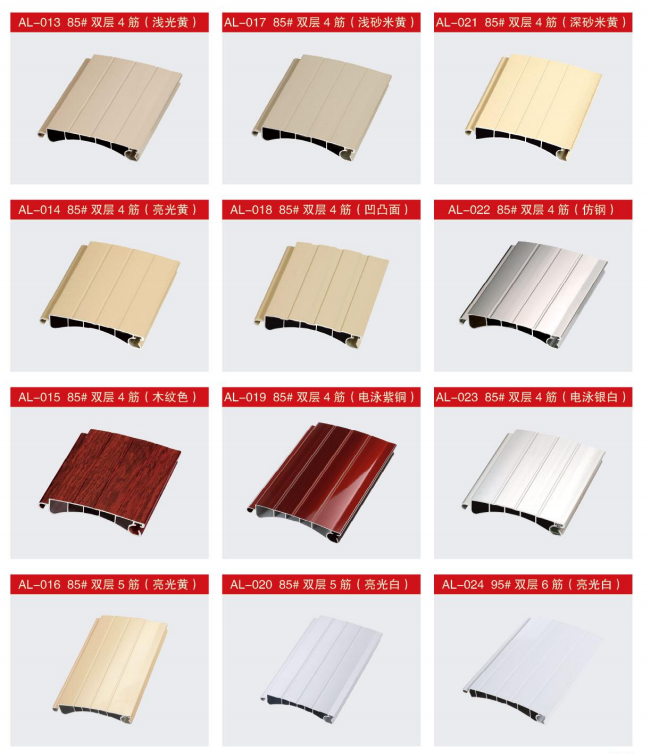

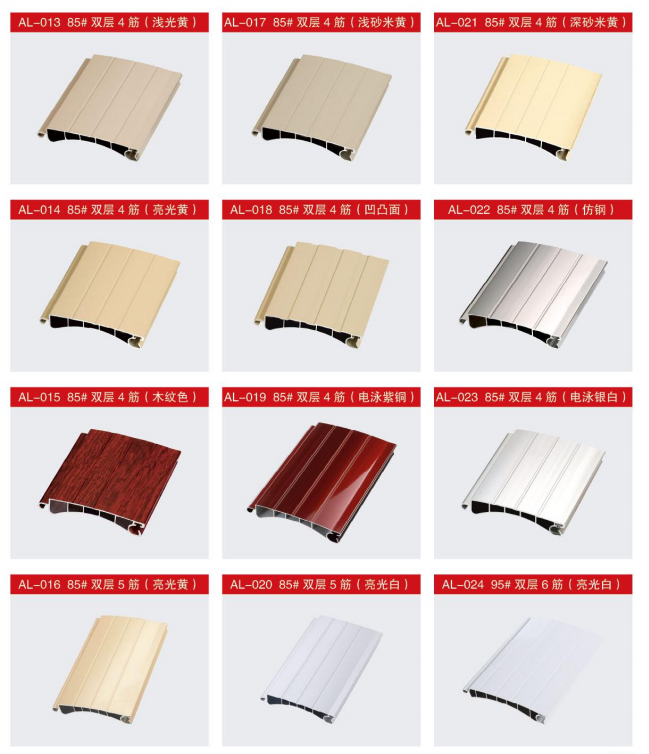

85# Double-Layer Four-Rib Slat (AL-013/AL-017/AL-021)

Parameters: 85mm width, 1.2mm thickness, 4-rib structure, 200MPa bending strength, 8.5kg/㎡ weight. Prevents sagging for 5–6m wide openings.

Surface Finishes: Glossy yellow (AL-013), light sand beige (AL-017), and dark sand beige (AL-021). A chain coffee shop using AL-017 reported a 12% increase in customer footfall.

3. 95# Series: Heavy-Duty for Extra-Wide Openings

95# Double-Layer Six-Rib Slat (AL-024)

Parameters: 95mm width, 1.5mm thickness, 6 reinforcing ribs, 12kg/㎡ weight, wind resistance grade 10 (0.65kPa). Suitable for openings up to 8m wide.

Structural Innovation: Double hollow design with transverse ribs limits deflection to ≤1/200 (e.g., 30mm sag for a 6m opening), ideal for mall entrances and logistics hubs.

4. Functional Slats: Foam-Filled and Hollow Designs for Specialized Needs

50# Foam-Filled Slat (AL-004)

Parameters: Filled with high-density polyurethane (40kg/m³), thermal conductivity ≤0.03W/(m·K), sound insulation ≥30dB, 7kg/㎡ weight.

Application: Cold storage facilities, recording studios, and KTVs. A fresh food supermarket using this slat reduced energy consumption by 25%, saving ~¥8,000 annually on electricity.

80# Single-Layer Perforated Slat (AL-008)

Parameters: Diamond-shaped hollow pattern (10×20mm holes), 40% ventilation rate, paired with anti-theft grilles. Used in equipment rooms and electrical substations needing heat dissipation.

III. Surface Treatment Processes for Aluminum Slats: Balancing Performance and Aesthetics

Surface treatments directly impact durability and decorative appeal. Choose based on environmental conditions:

1. Anodizing: Industrial Style with High Weather Resistance

Process Features: Electrolytic oxidation forms a 10–15μm film, offering metallic finishes (silver, bronze) and superior corrosion resistance. Ideal for coastal or industrial areas.

Limitations: Limited color options; scratches are irreparable. Best for utilitarian settings like factories and warehouses.

2. Powder Coating: Colorful Commercial Favorite

Process Features: Electrostatic powder application followed by high-temperature curing creates a 60–80μm coating. Covers full RAL color spectrum, with 0-level adhesion (GB/T 9286) and weather resistance ≥8,000 hours (10 years outdoor use).

Case Example: AL-009 glossy blue slats in a children’s playground resist graffiti and retain color after cleaning with detergents.

3. Wood-Grain Transfer Printing: High-End Simulation

Process Features: Heat transfer technology replicates wood textures with 95% realism, costing 1/3 of solid wood while avoiding cracking and termite damage.

Representative Models: AL-006 (50# wood grain), AL-015 (85# wood grain) for Chinese-style shops and luxury hotel lobbies.

IV. Five-Dimensional Decision Model for Aluminum Slat Selection

Opening Size Matching

<2.5m wide → 37#/50#; 2.5–5m → 80#/85#; >5m → 95#.

For heights >4m, use ≥85# slats with transverse reinforcing rods (≤1.5m spacing).

Environmental Factors

Coastal/humid areas → Anodizing or powder coating (≥80μm film);

High-corrosion industrial zones → 316 stainless steel screws + aluminum slats;

Cold regions → Foam-filled slats + heated guide rails (anti-freezing).

Functional Priorities

Insulation/soundproofing → 50#/85# foam-filled slats;

Ventilation/heat dissipation → 80# perforated slats;

Aesthetics → 85# wood-grain/copper-like slats.

Budget Control

Basic option: 37#/50# powder-coated slats (cost-effective);

Mid-to-high end: 85# multi-rib + custom colors (commercial display);

Luxury custom: 95# six-rib + copper/wood grain (brand flagship stores).

Installation and Maintenance

Choose slats with anti-derailment devices (e.g., AL-024 bottom anti-jump design) to reduce maintenance;

Clean quarterly with neutral detergent to avoid acid/alkaline exposure.

V. Frequently Asked Questions (FAQ)

Q1: Are aluminum slats prone to deformation?

A: High-quality aluminum slats (e.g., 85# double-layer four-rib design) achieve 200MPa bending strength—exceeding ordinary steel slats (150MPa). Testing shows a 6m-wide opening using 85# slats deforms only 25mm under 0.6kPa wind pressure (well below the 50mm safety threshold), with no permanent deformation after 10 years of normal use.

Q2: How do surface treatments rank in durability?

A: Anodizing (15-year weather resistance) > Powder coating (10 years) > Wood-grain transfer (8 years). Prioritize anodizing or powder coating in coastal areas; wood-grain transfer works well in dry northern regions for enhanced aesthetics.

Q3: Is the insulation of foam-filled slats better than steel slats?

A: Yes. 50# foam-filled slats have a thermal conductivity of 0.03W/(m·K), vs. 50W/(m·K) for 0.5mm galvanized steel slats—1,600 times better insulation. For a 2.4×2.4m opening, foam-filled slats reduce winter heat loss by ~30%, saving ¥500–800 annually on heating costs.

Q4: Can aluminum slats be paired with automatic opening systems?

A: Absolutely. Their lightweight nature (65% lighter than steel) reduces motor load and extends system life. Recommend 500W motors for ≤85# slats and 750W motors for 95# slats, ensuring a safe operating speed of 0.15–0.2m/s.

Q5: How to assess aluminum slat quality?

A: Three checks: ① Measure thickness with calipers (85# slats should be ≥1.2mm); ② Test coating adhesion (high-quality powder coatings resist nail scratches); ③ Inspect structure (reinforcing ribs should be integrally extruded, not welded).

This guide equips readers with aluminum slat selection logic from specifications to surface treatments. Aluminum slats’ lightweight and customizable features make them ideal for commercial and residential use. For optimal results, consult manufacturers for structural calculations to ensure safe, stable operation tailored to specific opening sizes and environmental conditions.

Recommended Products

up to dateLuxemburg Automatic Door Accessories

- Manufacturers Foot Pedal Activator Safety Beam Photocell Barrier Sensor For Medical Sliding Doors

- Safety photoelectric switch for high-speed door sensors

- Durable PVC Fast Rolling Door Fittings for Enhanced Security

- Automatic Repair of Zipper Door Plastic/Polymer Rails

- Smart Automatic Door Sensor for Fast Rolling Access Control

- Soft Fast Gate Control System 1.5kw Servo Motor and Control Box

- Automatic Access Control Square Surface Mount Infrared Non-Contact Switch

- Explosion-Proof Reinforced Self-Limiting Electric Heating Belt

- Explosion-Proof Shielded Self-Controlling Temperature Electric Heating Belt

- Heating Belt for Anti-Freezing, Heating and Heat Preservation of Cold Storage Doors

- 40W flame retardant explosion-proof self-limiting electric heating belt

- High Speed Door Zippers Industrial Door Zippers

- Safety Beam Sensor Use for Automatic Door

- Wireless Hand Sensor Switch For Automatic Door

- Hospital Door Foot Sensor

- Automatic Sliding Door System Wireless Touch Press Switch

- Automatic Sliding Door IP65 Waterprooft Wireless Hand Press Switch

- Automatic Door Microwave Sensor

- Reflective Type Infrared Detector

- Automatic High Speed Door Infrared Radar Sensor CNB-204G