Introduction: Synergy Between High-Speed Doors and Industry 4.0

1. Technical Integration: Seamless Automation Compatibility

AGV/AMR Coordination:

Real-Time Communication: Equipped with 485 interfaces or wireless protocols (e.g., Wi-Fi, ZigBee), these doors synchronize with automated guided vehicles (AGVs) and autonomous mobile robots (AMRs). Upon detecting approaching vehicles, doors activate high-speed opening (0.8–2.5 m/s), ensuring uninterrupted material flow.

Customized Dimensions: Compact designs (e.g., 2m width × 2.5m height) minimize energy loss while optimizing AGV passage in confined spaces.

IoT and Data-Driven Management:

Embedded sensors and PLC systems transmit operational data (e.g., cycle frequency, error codes) to cloud platforms for remote monitoring. Predictive maintenance algorithms analyze trends to preempt issues like motor overheating or rail wear, reducing downtime.

2. Intelligent Control Systems: Balancing Safety and Efficiency

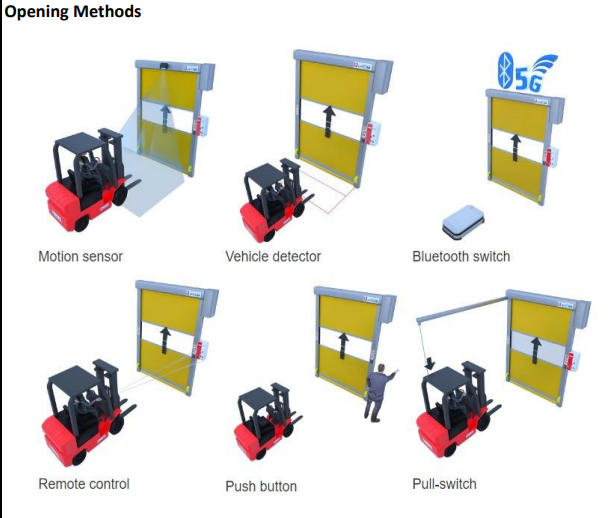

Adaptive Sensing Technologies:

Magnetic Induction: Detects metal objects (e.g., forklifts) via magnetic field changes, ideal for dusty or temperature-sensitive environments.

Radar Detection: Microwave sensors cover broader areas (5–8m range), enabling reliable operation in complex scenarios (e.g., multi-AGV workflows) unaffected by weather or lighting.

Safety Mechanisms:

Infrared light curtains and pressure-sensitive edges halt door movement upon detecting obstructions, preventing accidents.

Fire-resistant variants (compliant with DIN 4102) use flame-retardant materials (e.g., fiberglass-silicone coatings) for high-risk industrial zones.

3. Industry 4.0 Applications: Key Use Cases

Smart Logistics Centers:

In fully automated warehouses, doors integrate with AGVs and conveyor systems to enable 24/7 operations, reducing human intervention and energy consumption in cold storage/cleanroom environments (energy savings up to 30%).

Food and Pharmaceutical Manufacturing:

Dustproof seals (IP65-rated) and antimicrobial door curtains (e.g., PVC-polyester blends) maintain hygienic conditions, aligning with GMP and FDA standards.

Flexible Production Lines:

Modular designs allow rapid reconfiguration, such as in automotive welding shops, where doors adapt to dynamic layouts for mixed-model assembly.

4. Compliance and Sustainable Practices

Global Certifications:

CE (mechanical safety), UL (electrical safety), and ISO 9001 (quality management) ensure compliance for international markets.

Energy-efficient motors (≥90% efficiency) meet EU ErP directives, reducing carbon emissions.

Eco-Friendly Innovations:

Recyclable materials (e.g., aluminum frames) and low-power standby modes (<1W) support green building certifications like LEED.

5. Future Trends: Advancing Industry 4.0 Integration

5G and Edge Computing:

Ultra-low latency 5G connectivity enables real-time responses to MES commands, such as emergency shutdowns triggering synchronized door closures.

AI-Powered Predictive Analytics:

Machine learning models forecast component lifespan (e.g., spring fatigue cycles), enabling proactive replacements to avoid failures.

Digital Twin Simulations:

Virtual factory models test door performance under extreme conditions (e.g., typhoons, high traffic), optimizing operational logic and reliability.

Conclusion

High-speed roll-up doors have transitioned from passive barriers to active contributors in Industry 4.0 ecosystems. Their ability to harmonize with automation, IoT, and sustainability initiatives positions them as vital tools for enhancing productivity, safety, and environmental stewardship. As smart manufacturing evolves, these doors will continue to redefine their role in enabling agile, future-ready industrial operations.

Recommended Products

up to dateGuatemala Automatic Door Accessories

- Durable PVC Fast Rolling Door Fittings for Enhanced Security

- Automatic Repair of Zipper Door Plastic/Polymer Rails

- Smart Automatic Door Sensor for Fast Rolling Access Control

- Soft Fast Gate Control System 1.5kw Servo Motor and Control Box

- Automatic Access Control Square Surface Mount Infrared Non-Contact Switch

- Explosion-Proof Reinforced Self-Limiting Electric Heating Belt

- Explosion-Proof Shielded Self-Controlling Temperature Electric Heating Belt

- Heating Belt for Anti-Freezing, Heating and Heat Preservation of Cold Storage Doors

- 40W flame retardant explosion-proof self-limiting electric heating belt

- High Speed Door Zippers Industrial Door Zippers

- Safety Beam Sensor Use for Automatic Door

- Wireless Hand Sensor Switch For Automatic Door

- Hospital Door Foot Sensor

- Automatic Sliding Door System Wireless Touch Press Switch

- Automatic Sliding Door IP65 Waterprooft Wireless Hand Press Switch

- Automatic Door Microwave Sensor

- Reflective Type Infrared Detector

- Automatic High Speed Door Infrared Radar Sensor CNB-204G

- Aluminum Alloy Wind Section For PVC rapid roller shutter door

- Aluminum Bottom Section For PVC high speed rolling shutter door