About Zipper Rapid Door Drawings: An Understandable Technical Guide for Non-Experts

1. Understanding the Core Structure of Zipper Rapid Doors from the Drawing: Why Is It Called a "Zipper Door"?

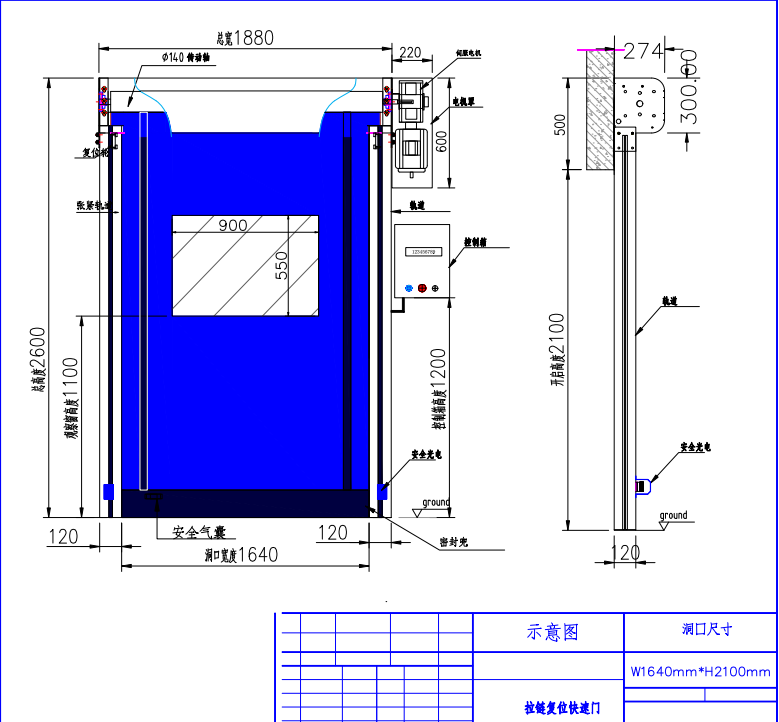

Main Door Body:

A blue PVC wear-resistant door curtain (the "observation window" in the drawing measures 900mm × 550mm for internal visibility) with a typical thickness of 1.2mm, featuring tear resistance, water resistance, and wind resistance.

Zipper Track:

The drawing’s right side shows the track is only 20mm wide, and the "zipper teeth" inside the track fully mesh with the door curtain edge. This enables the door to achieve capable of blocking dust and splashing water during operation.

Drive and Control Area:

The "motor cover" (600mm in height) at the top right of the drawing houses a high-speed motor, which, together with the "control box" (1200mm in height), enables the door to open/close at 0.8-1.5m/s—this is the origin of the term "rapid door."

2. Key Parameters in the Drawing: Numbers That Determine Door Performance

Opening Dimensions:

W1640mm × H2100mm (the "Opening Dimensions" section at the bottom of the drawing) — this is the door opening size the door fits. Common industrial door opening sizes range from 1m×2m to 5m×4m, and this size is suitable for small equipment passages and warehouse compartments.

Total Door Height:

2600mm (annotated as "Total Height 2600") — this includes the effective door curtain height of 2100mm plus the 500mm height of the top drive area, ensuring the door does not block the opening when fully retracted.

Sealing and Safety Components:

Safety Airbag:

The "safety airbag" at the bottom of the drawing triggers reverse ascent when the door encounters an obstacle while descending, preventing injury to personnel or damage to goods.

Sealing Brush Strip:

The "sealing brush strip" where the door sides contact the track, combined with the zipper structure, reduces the air leakage rate to less than 0.5m³/(h·㎡) after the door closes. This makes it suitable for environments requiring temperature control and dust prevention (e.g., food workshops, electronic warehouses).

3. Application Scenarios of Zipper Rapid Doors: Benefits That Ordinary Doors Cannot Provide

Food/Pharmaceutical Clean Workshops:

The seamless sealing of the zipper structure prevents external dust and insects from entering the workshop. Combined with rapid opening/closing (a 2-meter-tall door opens/closes in just 2 seconds at 1.2m/s), it reduces hot/cold air exchange—one food factory reduced its workshop temperature-control energy consumption by 18% after installation.

Logistics Warehouse Loading/Unloading Areas:

The door has an 8-level wind resistance rating (the zipper meshing enhances door stability), allowing it to withstand air disturbances in loading/unloading zones. Meanwhile, dual protection from the safety airbag and infrared sensors prevents collisions when forklifts enter/exit.

Noise Isolation Zones:

The combination of the PVC door curtain and sealing structure reduces noise by 15-20 decibels, making it suitable for high-noise equipment compartments in factories (e.g., air compressor rooms).

4. "Hidden Details" in Zipper Rapid Door Drawings: Safety and Durability in Design

Top Drive Shaft: The "Φ140 drive shaft" annotated in the drawing is made of thickened steel pipe, capable of withstanding the tensile force of long-term rapid door curtain operation, with a service life of over 100,000 cycles.

Safety Photoelectric Sensor: The "safety photoelectric sensor" on the right side of the drawing immediately stops and reverses the door if it detects an object below while descending, avoiding "blind spot pinching."

Sealing Bottom Pocket: The "sealing bottom pocket" at the door bottom fits closely to the ground, further enhancing dust and insect prevention.

Frequently Asked Questions (FAQ)

1. Does the "zipper" of a zipper rapid door break easily?

2. Can the opening/closing speed be adjusted?

3. What if there is a power outage?

4. Can it be customized for different door opening sizes?

Recommended Products

up to dateArgentina Automatic Door Accessories

- Manufacturers Foot Pedal Activator Safety Beam Photocell Barrier Sensor For Medical Sliding Doors

- Safety photoelectric switch for high-speed door sensors

- Durable PVC Fast Rolling Door Fittings for Enhanced Security

- Automatic Repair of Zipper Door Plastic/Polymer Rails

- Smart Automatic Door Sensor for Fast Rolling Access Control

- Soft Fast Gate Control System 1.5kw Servo Motor and Control Box

- Automatic Access Control Square Surface Mount Infrared Non-Contact Switch

- Explosion-Proof Reinforced Self-Limiting Electric Heating Belt

- Explosion-Proof Shielded Self-Controlling Temperature Electric Heating Belt

- Heating Belt for Anti-Freezing, Heating and Heat Preservation of Cold Storage Doors

- 40W flame retardant explosion-proof self-limiting electric heating belt

- High Speed Door Zippers Industrial Door Zippers

- Safety Beam Sensor Use for Automatic Door

- Wireless Hand Sensor Switch For Automatic Door

- Hospital Door Foot Sensor

- Automatic Sliding Door System Wireless Touch Press Switch

- Automatic Sliding Door IP65 Waterprooft Wireless Hand Press Switch

- Automatic Door Microwave Sensor

- Reflective Type Infrared Detector

- Automatic High Speed Door Infrared Radar Sensor CNB-204G